A day in the life of a student in the Indiana University Army ROTC program includes 5:30 a.m. wake-up calls, multiple workouts, classes, studying and training exercises. So when IU shifted to remote learning in early March, it didn’t take long for senior cadets Alex Combs and Kate Wampler to become restless.

A few weeks into the new normal, Wampler’s brother, who works at the General Motors plant in Kokomo, Indiana, told her the factory was hiring temporary employees to build ventilators. The couple knew they had to jump at the opportunity.

“We just really wanted to be able to look back at this time and say we were part of something that was helping people during the pandemic,” Wampler said.

General Motors signed a contract with the federal government in early April to produce 30,000 ventilators, in partnership with Ventec Life Systems, by the end of August. Production at the Kokomo plant began a few weeks later, and Wampler and Combs reported for duty April 20.

Combs’ job at the factory is on the sub assembly line – making each smaller part of the ventilator, pulling together the pieces and running the first test to make sure it has been assembled correctly. Then the ventilators head to Wampler’s unit, which runs additional tests. She and her co-workers hook the ventilators up to artificial lungs and ensure that they can run for 48 hours without disruption.

Neither Combs, who is studying criminal justice, psychology and Central Eurasian studies, nor Wampler, who is majoring in psychology, have prior experience working in a factory. They both said they faced a steep learning curve during the first week on the job. But they aren’t alone.

Many of their co-workers were new to the factory and new to the trade, having answered the call for temporary employees, and everyone works together to figure out new processes. Combs and Wampler are working beside restaurant managers, elementary school teachers and attorneys, all looking for a way to give back and stay busy while their day jobs have slowed down.

“There are a ton of new processes, so it’s very different even for the people who have been working at the plant for a while,” Combs said. “Things change every day, and no one has all of the answers, but everyone has been patient and willing to work together to figure things out.”

Factory work may be new to Combs and Wampler, but working in teams and thinking on their feet is something they did every day as cadets in the IU Army ROTC program. The long days of training also prepared them for the 48-hour weeks they’ve been working on the factory floor.

Everyone working at the factory is required to wear a mask and have their temperature checked before entering the building. Even though workers are encouraged to stay 6 feet apart when possible, Combs and Wampler get to enjoy lunch with each other every day, since they have both been staying with Wampler’s parents.

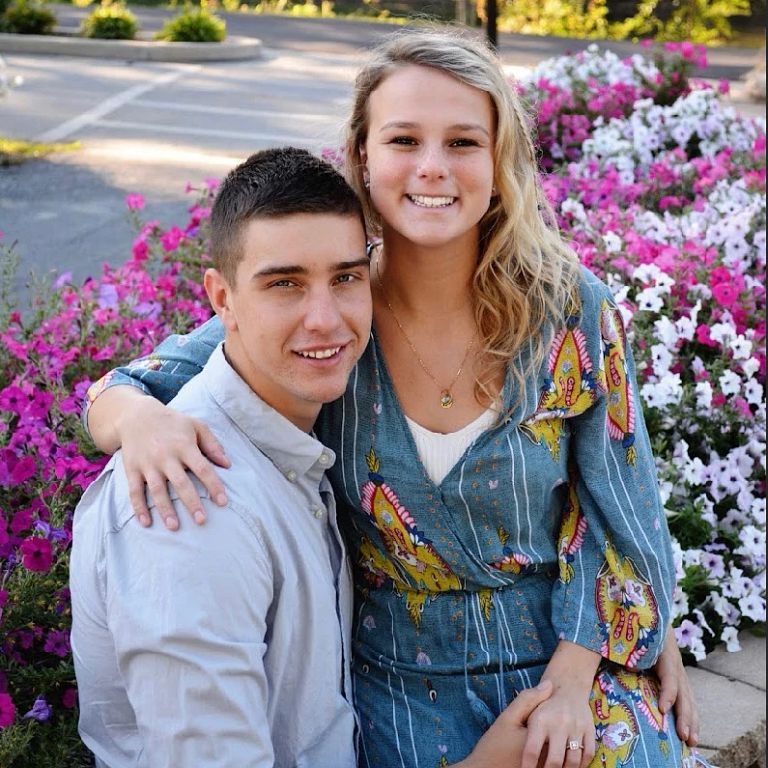

The couple, who are engaged to be married in September, plan to work at General Motors for as long as the program lasts or until November, when they move to Alabama for Combs’ training as a U.S. Army helicopter pilot. He and Wampler, who will train to become a chemical officer in the National Guard in early 2021, agree that this experience will give them valuable skills for their future careers.

“I think this experience has taught us not to let something that can feel big and scary be crippling,” Wampler said. “So far, we’ve been able to focus on the task at hand and let go of what can make us feel scared or anxious.”